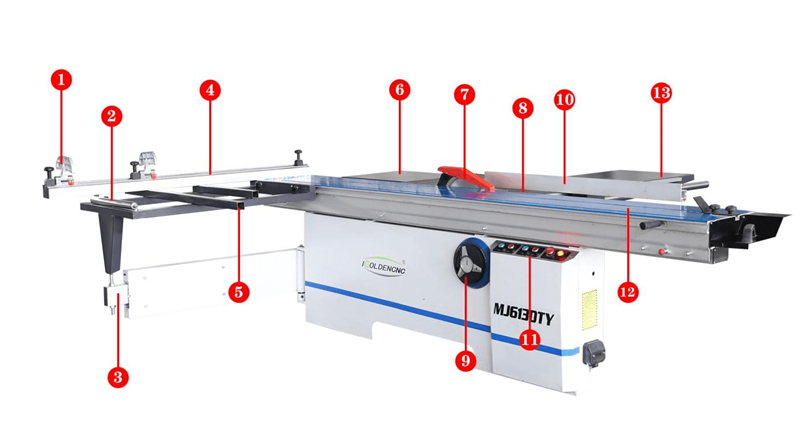

منشار الطاولة المنزلق لأعمال النجارة للبیع

یعتمد الاختیار على الاحتیاجات المحددة ومتطلبات الإنتاج لمحل النجارة أو المستخدم الفردی. اتبع دائمًا إرشادات السلامة المناسبة واستخدم معدات الحمایة الشخصیة عند تشغیل مناشیر الألواح أو أی آلات النجارة.

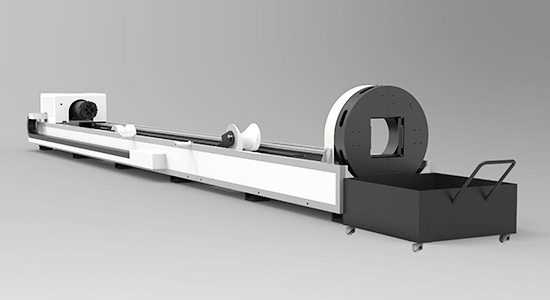

منشار شعاع الکمبیوتر، وأیضًا منشار لوحة الکمبیوتر، هو نوع من آلات منشار اللوحة یجمع بین تکنولوجیا التحکم العددی بالکمبیوتر. قد تشیر إلیها الشرکات المصنعة المختلفة على أنها آلة تحجیم اللوحة، أو منشار تقسیم اللوحة، أو منشار تحجیم اللوحة الأوتوماتیکی، أو مرکز تحجیم اللوحة.

إنها تعتمد التحکم الآلی بالکمبیوتر وعملیة التکامل بین الإنسان والآلة. یحتاج المشغلون إلى إدخال البیانات المطلوبة على شاشة اللمس. ومن ثم یتم تشغیل منشار قطع الألواح تلقائیًا من أجل قطع الألواح بدقة. مع التطور السریع لصناعة الأثاث، أصبحت متطلبات الدقة لمنشار قطع الألواح أعلى فأعلى.

أصبحت عیوب آلات منشار الألواح الیدویة أکثر وضوحًا: الدقة غیر الکافیة، والتقطیع، والأعطال، وإصابات العمل، وانخفاض الکفاءة، وما إلى ذلک. وقد أدى ظهور منشار طاولة الکمبیوتر للبیع إلى حل هذه المخاوف بشکل فعال.

ورأى لوحة

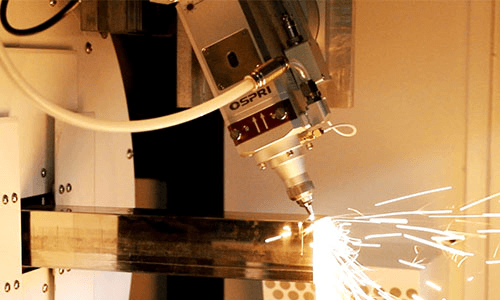

منشار الألواح عبارة عن آلة أعمال خشبیة مصممة لقطع الألواح الکبیرة أو صفائح الخشب بکفاءة ودقة، والخشب الرقائقی، وMDF (اللوح اللیفی متوسط ??الکثافة)، وغیرها من المواد المماثلة. إنه مفید بشکل خاص لمهام مثل قطع القطع الکبیرة لصنع الخزانات، إنتاج الأثاث، وغیرها من مشاریع النجارة.

یمکن لأداة الماکینة هذه قطع ومعالجة جمیع أنواع الألواح الخشبیة الصلبة والألواح الخشبیة وألواح ABS والألواح البلاستیکیة والزجاج العضوی والهیاکل الخشبیة الأخرى والألواح ذات الصلابة المماثلة. وهی من المعدات اللازمة لإنتاج الأثاث والدیکور والصناعات الأخرى.

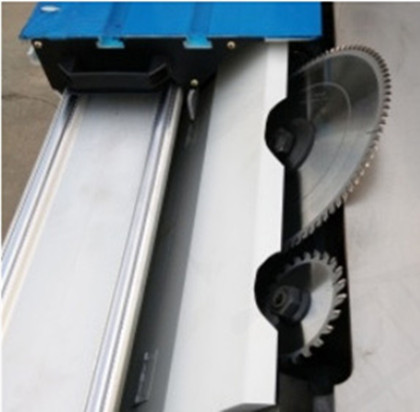

تتکون أداة الآلة من سریر، طاولة عمل متنقلة، دعامة مرفقة لطاولة عمل متنقلة، طاولة عمل ثابتة، منشار رئیسی، منشار ثانوی، آلیة رفع ناقل الحرکة، ولوحة توجیه أفقیة ورأسیة.

إن سکة توجیه الأدوات الآلیة مصنوعة من سکة توجیه خطیة من سبائک الألومنیوم، وهی مؤکسدة وتتمیز بمقاومة عالیة للتآکل ولا تشوه. لضمان أن أداة الآلة یمکن أن تعمل بدقة لفترة طویلة، یتم عرض زاویة میل شفرة المنشار الرئیسیة وشفرة المنشار المساعدة بصریًا بواسطة مقیاس الزاویة الدقیقة، وتکون العملیة مریحة للغایة.

المنشار المنزلق

منشار الطاولة المنزلق هو نوع من آلة النجارة تستخدم لعمل قطع مستقیمة فی الخشب والمواد الأخرى. یتمیز بطاولة منزلقة تسمح بتوجیه قطعة العمل بسلاسة عبر شفرة القطع. الطاولة المنزلقة هی المیزة الأساسیة لمنشار الطاولة المنزلق. إنه یوفر الدعم والثبات لقطعة العمل بینما یسمح لها بالانزلاق بسلاسة ودقة عبر الشفرة. یمکن تعدیل الطاولة المنزلقة لأطوال مختلفة، وتستوعب أحجامًا مختلفة من قطع العمل.

علاوة على ذلک، یمکنها أیضًا عمل الأخادید فی أی زاویة (على سبیل المثال 22.5 درجة، 45 درجة، 90 درجة). یمکن تحقیق ذلک عن طریق ضبط زاویة وارتفاع شفرة آلة منشار اللوحة. فی نفس الوقت، یمکن لآلة منشار الألواح أیضًا أن ترى جمیع أنواع الألواح العازلة، وألواح الألومنیوم الرقیقة، ومقاطع الألومنیوم.

منشار لوحة 90 درجة

یمکنها فقط قص الزوایا القائمة وتستخدم فی إنتاج ألواح الأثاث والخزائن ودوالیب الملابس وصناعات البناء الأخرى.

منشار لوحة 45 درجة

یمکن إمالة شفرة المنشار، ولا یمکنها قطع الزوایا القائمة فحسب، بل یمکنها أیضًا قطع الألواح من 0 إلى 45 درجة للأثاث الخشبی الصلب والأکیاس الناعمة.

المیزات والفوائد الرئیسیة لمنشار الطاولة المنزلق

انزلاق الجدول: الجدول المنزلق هو المیزة الأساسیة لـ أ رأى الجدول انزلاق. إنه یوفر الدعم والثبات لقطعة العمل بینما یسمح لها بالانزلاق بسلاسة ودقة عبر الشفرة. یمکن تعدیل الطاولة المنزلقة لأطوال مختلفة، وتستوعب أحجامًا مختلفة من قطع العمل.

زیادة قدرة القطع: تتمتع مناشیر الطاولة المنزلقة عادة بقدرة قطع أکبر مقارنة بمناشیر الطاولة التقلیدیة. تسمح الطاولة المنزلقة بقطع قطع العمل الأطول والأوسع بسهولة، مما یجعلها مثالیة لقطع الألواح الکبیرة أو الصفائح أو الخشب ذی الأبعاد.

تخفیضات دقیقة ومستقیمة: تضمن آلیة الطاولة المنزلقة إجراء عملیات قطع دقیقة ومستقیمة. تظل قطعة العمل ثابتة ومستقیمة طوال عملیة القطع، مما یقلل من مخاطر الأخطاء ویحسن الدقة الإجمالیة للقطع.

التنوع: یمکن لمناشیر الطاولة المنزلقة تنفیذ مجموعة واسعة من مهام القطع. بالإضافة إلى القطع المستقیمة، یمکن استخدامها أیضًا فی القطع المائل والقطع المتری وحتى بعض عملیات النجارة اعتمادًا على المیزات والملحقات المتوفرة.

میزات السلامة: غالبًا ما تکون مناشیر الطاولة المنزلقة مجهزة بمیزات أمان مثل واقیات الشفرات وسکاکین التقطیع وأجهزة مکافحة الارتداد. تساعد هذه المیزات على حمایة المشغل من الحوادث المحتملة وضمان التشغیل الأکثر أمانًا.

فعالة وموفرة للوقت: تتیح آلیة الطاولة المنزلقة التعامل مع المواد بکفاءة وسلاسة، مما یقلل الحاجة إلى التغذیة الیدویة ویحسن سیر العمل. وهذا یمکن أن یوفر الوقت ویزید الإنتاجیة، خاصة عند العمل مع قطع عمل أکبر أو أثقل.

التطبیقات المهنیة والصناعیة: تُستخدم مناشیر الطاولة المنزلقة بشکل شائع فی ورش الأعمال الخشبیة الاحترافیة والإعدادات الصناعیة حیث یتم تنفیذ مهام القطع کبیرة الحجم وعالیة الدقة. غالبًا ما یتم تفضیلها من قبل صانعی الخزانات ومصنعی الأثاث وغیرهم من المتخصصین فی الأعمال الخشبیة.

عند اختیار منشار اللوحة، ضع فی اعتبارک عوامل مثل حجم الماکینة وقدرتها، وقوة المحرک وسرعته، ومیزات الأمان المتوفرة، وجودة البناء الشاملة. من المهم اختیار منشار اللوحة الذی یناسب احتیاجاتک المحددة وأنواع المواد التی تعمل بها.