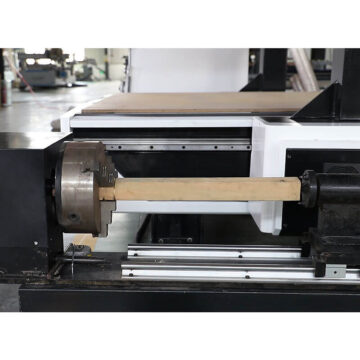

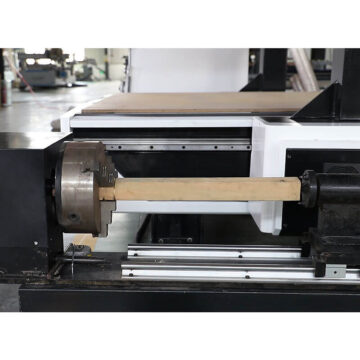

ATC CNC router machine has two types of tool magazines: linear and carousel. Both of them can be installed beside the spindle or on the side of the machine bed. By changing different tools automatically, the ATC CNC machine can complete multiple and complex woodworking processes at one operation. It can realize cutting, carving, engraving, drilling, routing, grooving, and pocketing of wood, MDF, acrylic, PVC, plastic, foam, stone, soft metal and other materials. It is also called ATC CNC wood carving machine, wood engraving machine. Basic type 3 Axis ATC CNC can be upgraded to be 4 Axis, 5 Axis, Routary type, etc.

ATC CNC Router is the abbreviation of Auto Tool Changer CNC Router, also be named as Heavy Duty CNC Router. An Automatic tool changer or ATC is used in the CNC Router machine to improve the production and tool carrying capacity of the machine. ATC changes the tool very quickly, reducing the non-productive time. Generally, it is used to improve the capacity of the machine to work with a number of tools. It is also used to change worn out or broken tools. It is one more step towards complete automation.

How many kinds of ATC CNC Router are there?

Normally there are two types of tool magazines. One is carousel type and with 8 positions or 10 positions or more positions. This ATC system is the fastest method of changing tools on a regular basis. Another is a linear type tool magazine. This tool magazine is very simple. But it is easy to operate and learn. And it is also very stable.

High quality ATC CNC router wood is suitable for the processing of various complex products or a variety of processing. It can be equipped with 6, 8, 10, 12 tools according to the different production process requirements of customers. There are two tool change modes for inline tool change and disc tool change. Widely used, including engraving, milling, chamfering, side milling, drilling, cutting, grooving, etc.

The most popular, industrial 3 axis ATC CNC router, perfect for professional CNC users, the Z series offers the robust construction that iGOLDENCNC products are known for, combined with a competitive set of configurations.

1325 atc cnc router 1530 2030 2130 3d wood cutting machine woodworking machinery with linear or carousel tool changer.

High Quality ATC CNC Router Wood Feartures

A.The machine used for panel furniture and board cabinet processing ,widely used in cutting ,drilling ,sloting ,milling etc .

B. Heavy stell structure body to keep machine strong for heavy cutting working .

C.Automatic oil lubrication system to keep machine long time working and using life .

D.Machine have self-protect design ,Only cycline closer the machine can working .

E. Well compatibility: CAD/CAM designing software, such as type3/ucancam/artcam, etc.

F. This machine has the function of re-carving after break point or power failure and it can estimate the processing time.

G: Manual/automatic oil-injection system allows the machine maintenance mush easier.

The performance of the cheap woodworking cnc router itself is important, but the choice of woodworking cnc router machine tools also affects the processing effect and processing efficiency. You get what you pay for, no matter what kind of things we buy, this sentence makes a lot of sense. A good woodworking cnc router machine has high machine configuration and good quality accessories, and the price is definitely high.

1. Woodworking Industry: Stereo wave board processing, wooden door, cabinet making and other furniture production.

2. Advertising Industry: Label making, PVC plate, PCB board (drilling and engraving), double color boards, logo production,

acrylic cutting, plastic suction for making advertising dedication, word cutting, sign making, crystal word, LED display screen, doorplate, nameplate, etc.

3. Artwork industry: solid wood, MDF, artificial stone, bamboo, marble, organic board, double-color board etc.

4. Mold Industry: Wood mold, foam mold and metal mold, etc.

5. Musical instrument industry: Instrument 3D surface carving, shape cutting

6. Woodcrafts.

7. Exhibition industry: Showcase.

is the machine of choice if your woodwork is headed in the direction of mass-produced parts with a small margin for error.

is the machine of choice if your woodwork is headed in the direction of mass-produced parts with a small margin for error.